Hafnium oxide deposition (CVD): Difference between revisions

(→Links) |

|||

| Line 29: | Line 29: | ||

===Links=== | ===Links=== | ||

Study HfO<sub>2</sub> formation: https://iopscience.iop.org/article/10.1149/MA2005-02/13/547/pdf | Study HfO<sub>2</sub> formation: https://iopscience.iop.org/article/10.1149/MA2005-02/13/547/pdf | ||

A Japenese paper how they grew it with an LPCVD: http://www.trichemical.com/topics/Manuscript%20revisions.pdf | |||

Revision as of 12:25, 12 October 2022

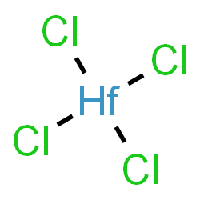

The base of this chemical recipe and processing is Hafnium-Tetrachloride, as it can be seen in the picture.

You might notice that Hafnium-Tetrachloride is a solid crystal at room temperature, which is kind of a problem considering that we wanna use it as a vapor in our CVD furnace, in order to react it with oxide for obtaining a Hafnium-Oxide thin film layer.

The equipment required for this process are a CVD and a plasma cleaner for removing impurities after the Hafnium oxide deposition

Chemical properties of Hafnium-Tetrachloride

HfCl4 can be produced by several related procedures:

- The reaction of carbon tetrachloride and hafnium oxide at above 450 °C;

- HfO2 + 2 CCl4 → HfCl4 + 2 COCl2

- Chlorination of a mixture of HfO2 and carbon above 600 °C using chlorine gas or sulfur monochloride:

- HfO2 + 2 Cl2 + C → HfCl4 + CO2

- Chlorination of hafnium carbide above 250 °C.

The result of those chemical reactions is a crystalline powder with a melting point of 432 °C

Processing steps

Since HfCl4 is a solid salt at room temperature, we dissolve it in Cyclohexane (C6 H11), with a concentration range of 0.01-1.0M, and use direct liquid injection for using it in our CVD as the precursor.

The waste result is hydrochloric acid, CO2 and H2O which needs, to be continuously flushed out with a gas like Argon

Links

Study HfO2 formation: https://iopscience.iop.org/article/10.1149/MA2005-02/13/547/pdf

A Japenese paper how they grew it with an LPCVD: http://www.trichemical.com/topics/Manuscript%20revisions.pdf