Hafnium oxide deposition (CVD): Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

The equipment required for this process are a CVD and a plasma cleaner for removing impurities after the Hafnium oxide deposition | The equipment required for this process are a CVD and a plasma cleaner for removing impurities after the Hafnium oxide deposition | ||

Revision as of 14:18, 12 October 2022

The equipment required for this process are a CVD and a plasma cleaner for removing impurities after the Hafnium oxide deposition

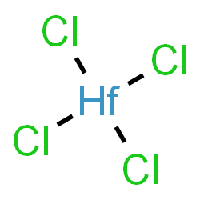

Chemical properties of Hafnium-Tetrachloride

HfCl4 can be produced by several related procedures:

- The reaction of carbon tetrachloride and hafnium oxide at above 450 °C;

- HfO2 + 2 CCl4 → HfCl4 + 2 COCl2

- Chlorination of a mixture of HfO2 and carbon above 600 °C using chlorine gas or sulfur monochloride:

- HfO2 + 2 Cl2 + C → HfCl4 + CO2

- Chlorination of hafnium carbide above 250 °C.

The result of those chemical reactions is a crystalline powder with a melting point of 432 °C

Processing steps

Since HfCl4 is a solid salt at room temperature, we need to first create a liquid precursor, and use direct liquid injection for using it in our CVD.

The process is based on a Japanese paper and requires a complex precursor.

The synthesis of this the Hf precursor TDEAH (Hf(NEt2)4) is so complex, that it needs its own page.

Links

Study HfO2 formation: https://iopscience.iop.org/article/10.1149/MA2005-02/13/547/pdf

A Japanese paper how they grew it with an LPCVD: http://www.trichemical.com/topics/Manuscript%20revisions.pdf