Hafnium oxide deposition (CVD): Difference between revisions

| (42 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

The | The equipment required for this process are a CVD and a plasma cleaner for removing impurities after the Hafnium oxide deposition | ||

Since HfCl<sub>4</sub> is a solid salt at room temperature, we need to first create a liquid precursor which can be turned into a vapor. | |||

The process is based on a [https://download.libresilicon.com/papers/HafniumOxide.pdf Japanese paper] and requires a complex precursor. | |||

The | The synthesis of the [[Hf precursor TDEAH (Hf(NEt2)4)]] is so complex, that it needs its own page. | ||

===Precursor injection=== | |||

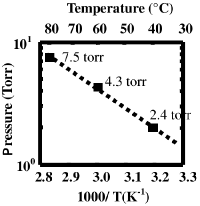

[[File:Pressure_TDEAH.png|200px|right|thumb|Vapor pressure]] | |||

Introduce TDEAH gas into the deposition chamber using a bubbling system, use N<sub>2</sub> as the carrier gas. | |||

To prevent liquefaction of the source before it enters the deposition chamber, maintain the line from the bubbler to the chamber at a temperature of 85°C. | |||

Heat the bubbling system chamber to 80°C. | |||

The flow rate into the CVD chamber should be 40 sccm. | |||

===Oxidizer injection=== | |||

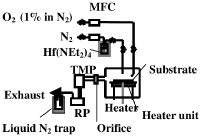

[[File:HFO2_CVD_setup.png|200px|right|thumb|CVD setup]] | |||

Have O<sub>2</sub> in N<sub>2</sub> in a ration 1:99 and feed it into the chamber through a separate nozzle, because otherwise the O<sub>2</sub> decomposes the TDEAH before it can reach the substrate. | |||

The | The flow rate can be varied between 0 and 20 sccm, for obvious reasons you want it higher than zero, because without oxygen you won't get any oxide. | ||

===Substrate/CVD chamber temperature=== | |||

Set a temperature between 300°C and 450°C, in order to control deposition speed. | |||

===CVD chamber pressure=== | |||

Set the pressure within the CVD chamber to 1 torr | |||

===Equipment=== | |||

* Potential CVD furnaces: | |||

** https://www.digiqualsystems.com/products/furnaces/tubular-furnace/horizontal-tubular-furnace/ | |||

** https://www.mtixtl.com/ThreeZonesTubeFurnaceHighVacuumMFCGas-OTF-1200X-III-HVC-UL.aspx | |||

* Bubblers: | |||

** https://www.mtixtl.com/Bubbler/Evaporatorforliquidsourcesandchemicalprecursors-BL-SS.aspx | |||

* Mass flow meters | |||

** https://www.mtixtl.com/Liquid-delivery-system.aspx | |||

Latest revision as of 17:33, 14 October 2022

The equipment required for this process are a CVD and a plasma cleaner for removing impurities after the Hafnium oxide deposition

Since HfCl4 is a solid salt at room temperature, we need to first create a liquid precursor which can be turned into a vapor.

The process is based on a Japanese paper and requires a complex precursor.

The synthesis of the Hf precursor TDEAH (Hf(NEt2)4) is so complex, that it needs its own page.

Precursor injection

Introduce TDEAH gas into the deposition chamber using a bubbling system, use N2 as the carrier gas.

To prevent liquefaction of the source before it enters the deposition chamber, maintain the line from the bubbler to the chamber at a temperature of 85°C.

Heat the bubbling system chamber to 80°C.

The flow rate into the CVD chamber should be 40 sccm.

Oxidizer injection

Have O2 in N2 in a ration 1:99 and feed it into the chamber through a separate nozzle, because otherwise the O2 decomposes the TDEAH before it can reach the substrate.

The flow rate can be varied between 0 and 20 sccm, for obvious reasons you want it higher than zero, because without oxygen you won't get any oxide.

Substrate/CVD chamber temperature

Set a temperature between 300°C and 450°C, in order to control deposition speed.

CVD chamber pressure

Set the pressure within the CVD chamber to 1 torr

Equipment

- Potential CVD furnaces:

- Mass flow meters