Danube River: Difference between revisions

No edit summary |

|||

| Line 1: | Line 1: | ||

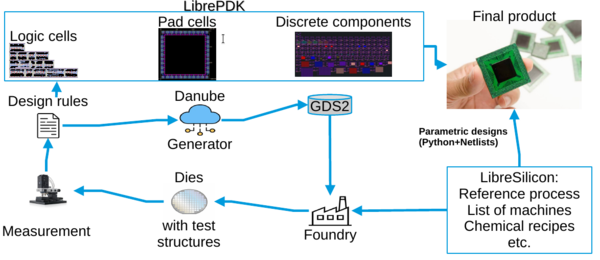

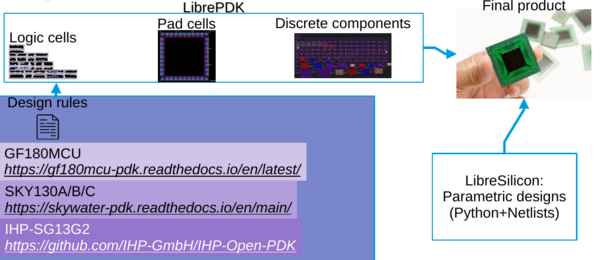

[https://gitlab.libresilicon.com/generator-tools/danube-river Danube River] is a tool, which generates you GDS2 files which you then can manufacture with your prototype process flow in order to validate parameters and adjust your recipes until the values are within a desired range. | [https://gitlab.libresilicon.com/generator-tools/danube-river Danube River] is a tool, which generates you GDS2 files which you then can manufacture with your prototype process flow in order to validate parameters and adjust your recipes until the values are within a desired range. | ||

== Use cases == | |||

=== Setting up a new fab === | |||

In case you wanna build a new factory, you basically tape out your Danube River layout over and over again while adjusting the recipes and design rules until the structures aren't broken anymore under the microscope and the values you measure match the predictions you've calculated. | |||

[[File:Danube For New Foundry.png|none|thumb|600x600px|Danube River flow for setting up a new fab]] | |||

=== Setting up support for an existing fab === | |||

In case you already have a working process and foundry available, but you're not sure that the timing characteristics they've provided are accurate, you can use Danube River for extracting your own timing characteristics. | |||

[[File:Danube For Existing Foundry.png|none|thumb|600x600px|Danube River flow for supporting existing process]] | |||

== Successful tapeout == | |||

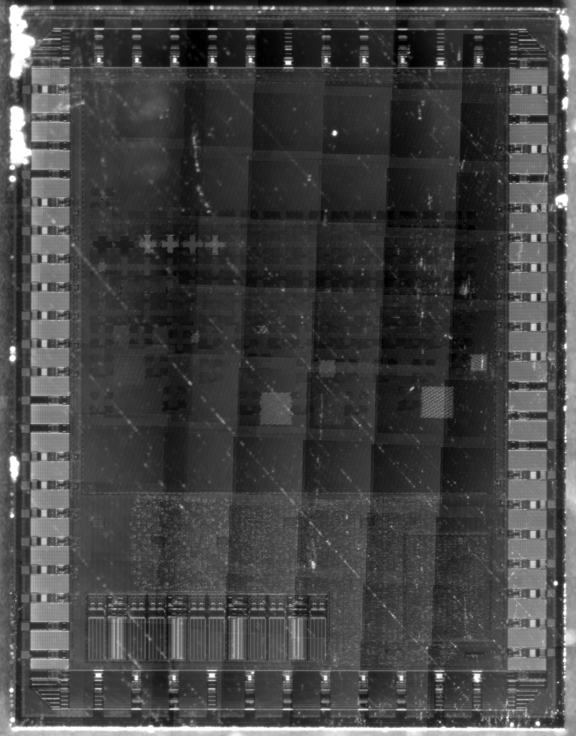

So far, the only opportunity we had to try the new test layout generator, was with Global Foundries on their 180nm node, of which the result can be seen in the picture below: | So far, the only opportunity we had to try the new test layout generator, was with Global Foundries on their 180nm node, of which the result can be seen in the picture below: | ||

[[File:Danube GF180.png|A successful tapeout with GF180|alt=A successful tapeout with GF180|frame|none]] | [[File:Danube GF180.png|A successful tapeout with GF180|alt=A successful tapeout with GF180|frame|none]] | ||

Revision as of 19:30, 2 December 2024

Danube River is a tool, which generates you GDS2 files which you then can manufacture with your prototype process flow in order to validate parameters and adjust your recipes until the values are within a desired range.

Use cases

Setting up a new fab

In case you wanna build a new factory, you basically tape out your Danube River layout over and over again while adjusting the recipes and design rules until the structures aren't broken anymore under the microscope and the values you measure match the predictions you've calculated.

Setting up support for an existing fab

In case you already have a working process and foundry available, but you're not sure that the timing characteristics they've provided are accurate, you can use Danube River for extracting your own timing characteristics.

Successful tapeout

So far, the only opportunity we had to try the new test layout generator, was with Global Foundries on their 180nm node, of which the result can be seen in the picture below:

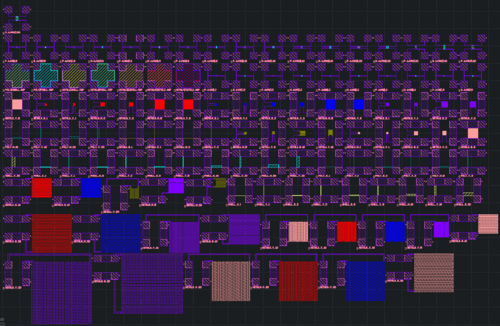

GDS2 view

The upper left section in the above image corresponds with the layout extracted from KLayout, when opening up the layout used for the tape-out

Structures

The Danube test wafer has the purpose of allowing to characterize basic analog properties resulting from the manufacturing process flow.

Each of those properties measured can be linked to a specific recipe in the process flow, which allows to fine tune a process and all its process recipes through repeatedly manufacturing and measuring the Danube river layout.

The Danube river contains 3 types of devices, which allows you to determine edge parameters:

- Resistors

- Capacitors

- Transistors

Resistors

Capacitors

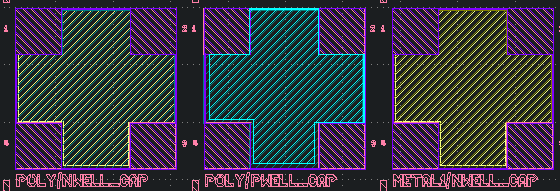

Below some of the capacitors on the test wafer can be seen in more detail.

Transistors

Measuring method

TODO: Elaborate Kelvin structures